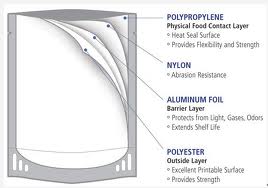

Just as politicians will say, "It's the economy," with stand up pouches, also known as stand up bags, is the layers that matter. The layers of film that is. A stand up pouch can be made using clear structures in case you want to see the contents, metalized film or Mylar, or even foil. But as I've mentioned earlier, a single layer of anything on a stand up bag serves very little purpose.

Just as politicians will say, "It's the economy," with stand up pouches, also known as stand up bags, is the layers that matter. The layers of film that is. A stand up pouch can be made using clear structures in case you want to see the contents, metalized film or Mylar, or even foil. But as I've mentioned earlier, a single layer of anything on a stand up bag serves very little purpose.

The first step with the design of stand up bags is really to find out what is being packaged. Is it flaky, powdering, coarse or even a liquid? Does it need protected from moisture, odor, vapor, or even sunlight? How will the product in stand up pouch be stored, in a hot warehouse or a freezer? How about more regarding the product itself, is it sticky, greasy, or filled with oil? From there we are able to make recommendations based upon what the client is hoping to achieve...meaning is the stand bag to keep the product fresh for the next year or just the next month, will the stand up pouch be printed or have a sticker applied? Again, this is based upon what the client is trying to achieve, not what we want to sell them. If your stand up bag supplier isn't looking out for your best interests, find another one, like us.

My point with all of this is the reason I put this 3 part series together. There is more to a stand up bag than most people realize. There is a tremendous amount of thought and design into the material itself and further if the stand up bag is printed. We have developed several online tools and our unique process to help our clients every step of the way, so not only is choosing the right material simple but so is the custom printed process if a client decides to go that direction.

stand up bag than most people realize. There is a tremendous amount of thought and design into the material itself and further if the stand up bag is printed. We have developed several online tools and our unique process to help our clients every step of the way, so not only is choosing the right material simple but so is the custom printed process if a client decides to go that direction.

Remember, at the end of the day, it all starts with the layers of film, end of story.