All around the world, food and agriculture agencies are making concerns about sugar intake a key priority.

In Jamaica, new standards for packaging and labeling sugar for retail distribution could have significant affects on the industry and the way manufacturers operate. In the United States, the FDA is close to making a decision on the proposal to require food companies to label percentages of added sugar on their product packaging. The need for consumer transparency and education is on the rise, and people certainly have a right to know how much sugar is in their products. However, sugar companies could take a hit if they do not follow the principles of authenticity, honesty, and ethical practices when presenting their products to consumers.

This is why packaging for granulated sugar can never be an afterthought – your sugar packaging is the first thing shoppers see on shelves, and if it features eye-catching colors and graphics, along with informative labels, consumers will be less likely to fear the sweet granular ingredient. Ten years ago, we began to see a transformation in the way sugar is packaged. Bulky paper sacks that are easy to rip and tear went by the wayside. Instead, granulated sugar companies started embracing stand up pouches, as they are much easier to handle, open, reclose, and maintain the freshness of the product. These bags, constructed with multiple laminated layers of FDA-approved plastic, are leak-proof and much less likely to result in product damage or waste before hitting retail locations.

Because stand up pouches for sugar are flexible, they can expand to hold larger quantities of the product while still standing upright on shelves. This allows brands to distinguish themselves through their creative package designs, while including easy-to-read labels that illustrate the benefits of this particular type of packaging. Lightweight packaging for granulated sugar is more environmentally friendly than cylindrical canisters that take up significant space in landfills, and they result in less packaging material waste than those cheap paper bags that rip and tear.

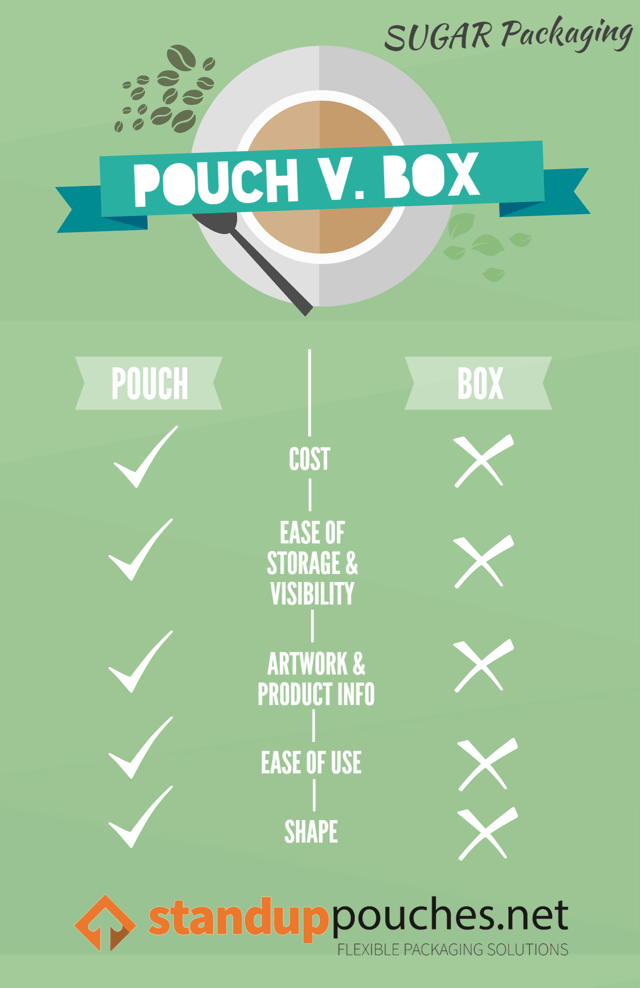

Puncture-resistant stand up pouches for sugar cost less than half of a cardboard box – though boxes still tend to have a higher presence in the market – and sugar companies that embrace flexible packaging are establishing themselves as both innovative and wise with their capital and resources.

The great thing about custom printed sugar packaging is that it allows companies to have more fun adding new features and colorful artwork to a product that – generally speaking – is hard to differentiate from one brand to the next. Stand up bags can be constructed in a variety of shapes, and they can feature additional user-friendly structural components like hang holes, tear notches, zip locks, and spouts. Each side of a pouch can be utilized to feature a sugar company’s branding, educational information, graphics, and the like – similar to cardboard sugar packaging, but better. Pouches can be produced with either a vibrant glossy finish, or a matte outer layer that many modern brands are embracing for its texture and uniqueness.

When it comes to packaging sugar, brands always need to keep the customer in mind and design their containers so they can be easily used and stored. People may be shying away from added sugar in their snacks and drinks, but there’s always going to be a market for this ingredient for at-home bakers and chefs. Restaurants, too, need to be able to easily use sugar for their meals and desserts without spilling or wasting the product. Pouches offer a unique shape that can suit the end user’s specific needs and help differentiate one great sugar brand from the competition.

Share this Image On Your Site

(Image Sources: Makro, BP&O)

Related Posts: